YieldPoint’s d-Cable technology provides engineers, technicians, consultants and contractors with a digital instrumented 7-strand cable for geotechnical monitoring. This instrument tracks how the load develops its own length of 7-wire stand cable bolt over time. It allows a reliable assessment of the Factor of Safety against cable rupture. The instrument is applicable to cable bolts, ground anchors, tendons, and tie-backs used in all types of mining and civil projects. It has the potential to help predict the risk of catastrophic structural failure: in fact d-Cable data can enhance many aspects of engineering design, installation quality control, long-term operation assessment, and rehabilitation. Click here for a case study.

The d-Cable is indistinguishable from a regular cable and deployment simply involves replacing a regular cable with its instrumented equivalent. During cementing/grouting no special procedures need to be followed. The readout head of the d-Cable has the same diameter as the 7-wire strand itself, and therefore grips and a jack can be applied over the readout head if the cable is to be plated. If no face-plate is required the readout head can simply be recessed into the collar of the hole.

Features:

- Instrumented 7-wire strand cable applicable to plain strand, bulb (Garford) cables

- Applicable to grouted cables and cables spun in resin

- Both Head-at-Collar (HAC) and Head-at-Toe (HAT) configurations possible

- HAT configuration routes leadwire through a continuous steel tube

- Available with 1 (d1Cable) to 6 (d6Cable) strain gauges

- Microcontroller provides output directly in displacement (mm)

- Individually calibrated, calibrations sheets available

- Immunity to hostile environment

- High survivability to shock and vibration

- Easy to install and maintain

- Digital (d-Tech) instrumented cable with RS485 signal out

Technology:

The d-Cable is based on a miniature borehole extensometer manufactured into a surrogate tubular king-wire. A total of up to six wires are fixed to the king-wire at nodal locations x1,x2……x6. Node 1 is always closest to the head. The translation of the six wires is measured by 6 displacement sensors at the head of the device. As the cable stretches each displacement sensor measures the relative displacement between the head and the nodal point (u1, u2 ….u6). The difference between adjacent nodal points can be used to calculate the strain of the cable, and this is converted to load in tonnes.

The technology can be manufactured in HAC or HAT configurations. The HAT configuration is suitable for cables that are installed with a face plate, and the leadwires are returned through a continuous stainless steel tube.

Manual Readout:

YieldPoint’s low cost geotechnical d-Reader readout unit or the new d-Tab (Android) cable.

Data-logging:

Data from the d-Cable can be collected using YieldPoint’s BluLink or d4BluLogger dataloggers. Data can be downloaded using the BluPoint App.

Automated data retrieval:

Clusters of instruments can be monitored wirelessly (BT5 beacons) using the BluGateway or if a wired connection is preferred the d4BluGateway. Data backhaul options include:

- Ethernet/WiFi: WiFi BluGateway, or

- Cellular: LTE BluGateway

- dMesh: a 900MHz 1 for 1 wireless mesh solution.

Case study 1: Tieback monitoring in Toronto

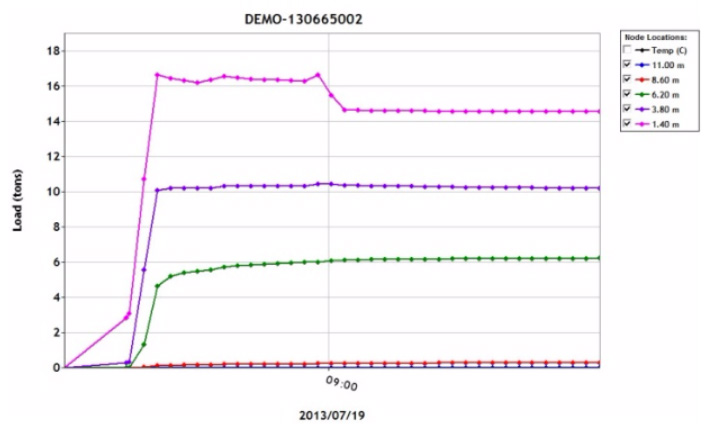

7-wire strand cables are widely used as tiebacks in civil engineering projects. YieldPoint has worked with Monir Precision Monitoring of Toronto, ON, to monitor tiebacks installed in the foundation of the 41-story BISHA condominium project.

The load and displacement profiles along the tiebacks were successfully monitored both (i) as the tiebacks were post-tensioned to 70% the capacity of the steel strand and (ii) as the foundation was fully excavated. Results for both tie-backs were similar, and only changed minimally in the period after post-tensioning.

The Load in the tieback recorded at 1min intervals during the post-tension process.

The project has recently topped out at the 41st story.

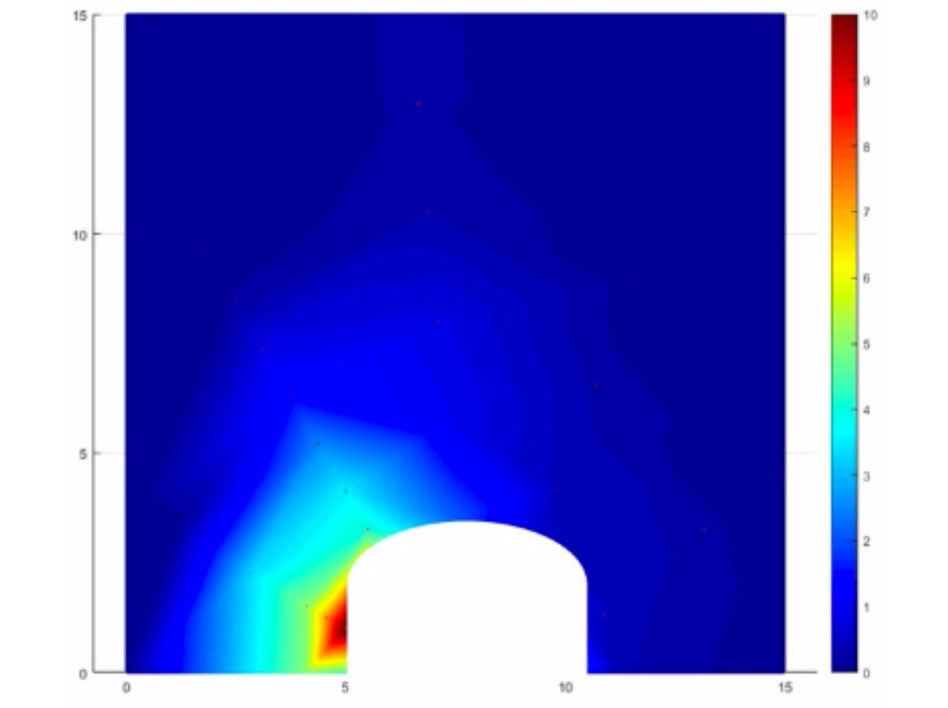

Case Study 2: Monitoring of a cable Bolt array

load and displacement on a full ring of cables around a development drive was determined using a YieldPoint’s d-Cables and d-EXTO at a Mine in Queensland Australia. The d-Cables can be used to measure both displacement and load. By contouring deformations the data from instruments can be easily compared with results from numerical simulations. In this case deformation was concentrated in one wall of the drive.